Precicut offers a range of wheel blast machines equipped with

skew roller type conveyors for surface cleaning of bars,

pipes and cylinders

Precicut offers a range of wheel blast machines equipped with

skew roller type conveyors for surface cleaning of bars,

pipes and cylinders

Precicut offers a range of wheel blast machines equipped with skew roller type conveyors for surface cleaning of bars, pipes and cylinders. The machines can be easily integrated in existing processes or can be used as standalone equipments. The machines are offered in single pass (one piece is fed a time) and multi-pass (more than one piece is blast cleaned at a time) models. The machines can be equipped with 8 blast wheels for high production demand.

The bar cleaning machines can handle a range of profiles like round, square and hexagonal bars. The customised skew roller conveyor along with strategically positioned blast wheels ensures thorough cleaning in a single pass and at desired line speed. For very high production requirement a range automated loading and unloading systems are offered.

The skew roller conveyor generates spiral motion which allows for thorough cleaning of pipes/cylinders externally. The machines are offered to accommodate any pipe diameter and lengths. The machines can be offered with internal cleaning equipment which will blast clean the internal surface of the pipes/cylinders

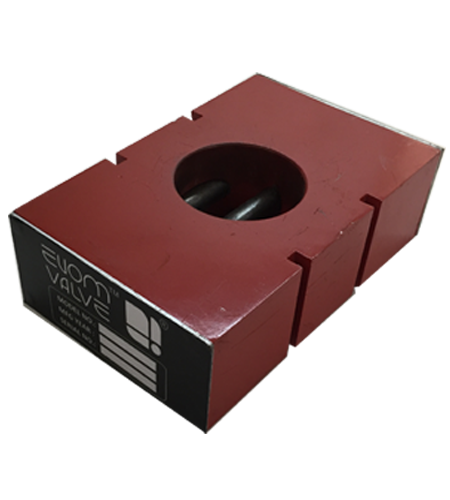

Euom Valve® is a cost effective and ultra modern shot flow control valve that uses an ingenious approach to achieve shot flow control. The valve operates on the theory of electro-magnetism

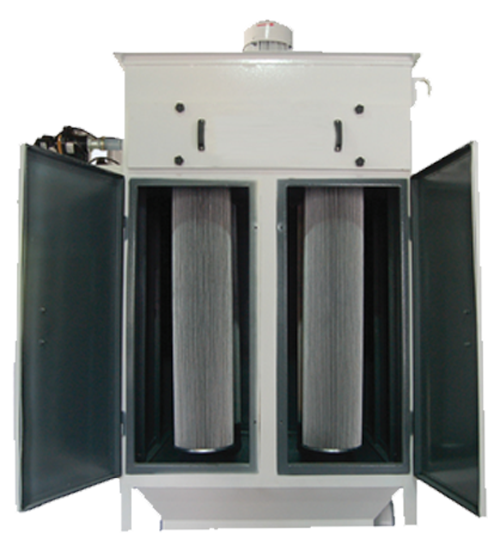

High Efficiency Reverse Pulse Jet Type Dust Collector

| Line Speed | Up to 30 mtrs/min, higher speeds can be provided as per requirement |

| Cross Section | |

| Diameter | 8mm and above |

| No of Blast Wheels | 1, 2, 3, 4, 6,8 |

| Blast Wheel Size [inches] | 12 / 15 |

| Blast Wheel Drive | Direct Drive or Indirect drive |

| Blast Wheel Design | Single plate or Double plate design |

| Shot Flow Control Valve | Euom Valve |

| Dust Collector | High Efficiency Reverse Pulse Jet Type |

| Power Requirement [Hp] | Variable, depending on machine configuration |

| Electricals |

• Main Supply: 440V, 50 Hz, 3 phase • Control Circuit and Instrumentation - 24Vdc. |