A continuous indexing hanger type design allows for

continuous production. The main chamber is divided

into two or more compartments,

each carrying one hanger.

A continuous indexing hanger type design allows for

continuous production. The main chamber is divided

into two or more compartments,

each carrying one hanger.

A continuous indexing hanger type design allows for

continuous production. The main chamber is divided

into two or more compartments,

each carrying one hanger.

A continuous indexing hanger type design allows for continuous production. The main chamber is divided into two or more compartments, each carrying one hanger. The shot blasting and part loading is carried out simultaneously (in different compartments). After end of cycle only the shot flow stops and the drum indexes to simultaneously present the next hanger for shot blasting and previous shot blasting hanger for part un-loading/loading.

These machines are suitable for robotic/automated part handling design and for integration with manufacturing cells.

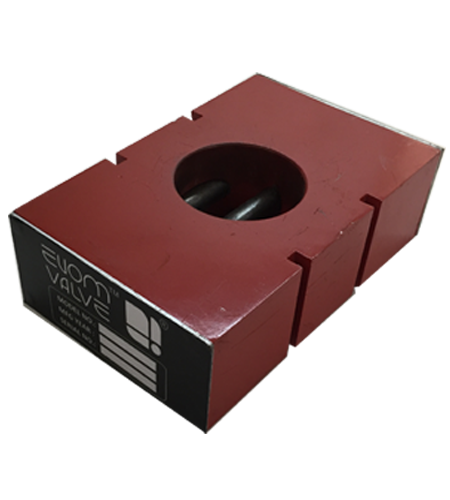

Euom Valve® is a cost effective and ultra modern shot flow control valve that uses an ingenious approach to achieve shot flow control. The valve operates on the theory of electro-magnetism

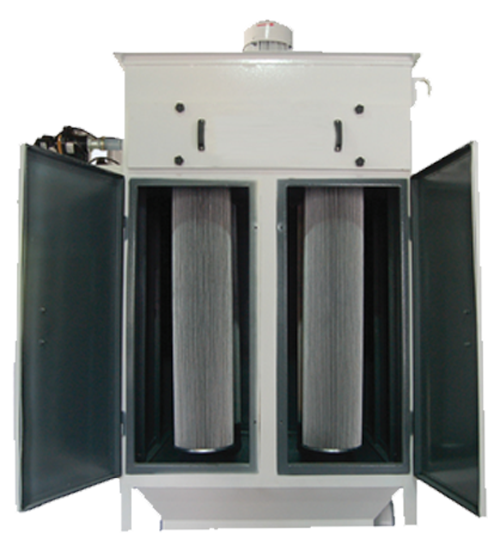

High Efficiency Reverse Pulse Jet Type Dust Collector

| MODEL | MiNi - T | GLINT-350T | GLINT-450T | GLINT-800T |

| Load Capacity [kgs] | Up to 150 | Up to 350 | Up to 450 | Up to 1500 |

| Hanger Dimensions [mm] | 300 X 900 | 600 X 1000 | 1000 X 1200 | Customized |

| No of Blast Wheels | 2 | 2 | 2 | 3, 4 |

| Blast Wheel Size [inches] | 12 | 15 | 15 or 19.5 | 15 or 19.5 |

| Blast Wheel Drive | Direct motor mounted or Indirect drive | |||

| Blast Wheel Design | Single plate or Double plate design | |||

| Shot Flow Control Valve | Electro-magnetic/Pneumatically operated | |||

| Turbine Motor [Hp] | 5/7.5 | 7.5/10 | 10/15 | 10 and above |

| Electricals |

• Main Supply: 440V, 50 Hz, 3 phase • Control Circuit and Instrumentation 24Vdc. |

|||

| Sound Level | <85 dB at a distance of 1 meter from the machine | |||

| Dust Collector | High Efficiency Reverse Pulse Jet Type Dust Collector | |||