Precicut Single Table Type Wheel Peening machines are

suitable for low to medium production demands.

Precicut Single Table Type Wheel Peening machines are suitable for low to medium production demands. These machines are custom designed to suit individual components as per their design and peening specifications.

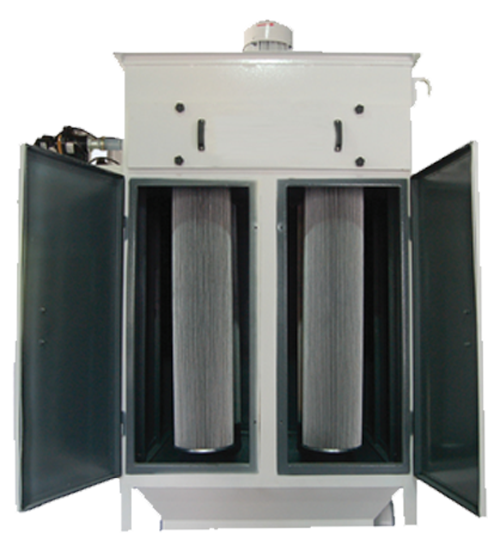

The machine consists of turbine unit, abrasive handling system, shot filtration system, vibro-sieve for shot size classification and precise shot flow control valves. The machine is also equipped with a dedicated cartridge type dust collector for dust removal.

The blast wheels are strategically located such that the shot flow is generated in a specific manner required for peening. This blast pattern varies as per each component and peening requirement.

During the peening process the component/stack rotates around its axis and is peened thoroughly inside the peening zone. The process parameters can be adjusted and monitored through the machine interface with advanced capabilities like report generation, SCADA, etc.

The machine is available in 2 configurations, double door type or turnstile type.

Vibro Screens are designed to perform effective size based separation in coarse as well as fine sizes. Vibro Screens use wire mesh or perforated or slotted sheets for carrying out separation of material on basis of size. They are designed on the principle of Gyratory Motion. Vibro screens allow remove the unacceptable sized shots/particles from the machine. The particles which are larger than the designated shot size can cause damage to the component and create dents. On the other hand, under-sized particles shall deteriorate the shot peening intensity and make the system incapable of generating the desired compressive stresses.

Vibro screens are mandatory in shot peening applications as the shot size is very crucial factor for permanent stress generation. The correct size shots will only create the desired stress pattern in the component.

Euom Valve® is a cost effective and ultra modern shot flow control valve that uses an ingenious approach to achieve shot flow control. The valve operates on the theory of electro-magnetism.

High Efficiency Reverse Pulse Jet Type Dust Collector

| Peening Envelope | Customized |

| Production Rate | |

| Shot Velocity | Up to 90 mtrs/sec |

| Shot Size Classification | Vibratory Classifier |

| Shot Flow Control | Euom Valve |

| Blast Wheel RPM | Up to 3600 RPM |

| Job Rotation Speed | Variable, 5 - 25 RPM |

| Input / Output Height | 1000 approx |

| Dust Collector | High Efficiency Pulse Jet Type with additional fine filter and silencer at the blower outlet |

| Sound Level | <85 dB at a distance of 1 meter from the machine |